How to Prevent Rust on Nails Used in Nigerian Houses

Rusting is a common issue in Nigerian homes, particularly due to the humid climate, frequent rainfall, and poor-quality construction materials. When nails rust, they weaken, compromising the integrity of wooden structures, roofs, and furniture. Over time, this can lead to costly repairs or even structural failures.

Understanding the causes of rust and how to prevent it is essential for builders, homeowners, and construction professionals in Nigeria. This article will explore practical strategies to prevent nail rust, ensuring durability and longevity in home construction.

Understanding Why Nails Rust

Rust, scientifically known as iron oxide, forms when iron or steel comes into contact with oxygen and moisture over time. In the context of Nigerian houses, several factors accelerate the rusting process:

Common Causes of Nail Rust in Nigeria

- High Humidity Levels – Coastal regions such as Lagos and Port Harcourt experience high humidity, which speeds up corrosion.

- Exposure to Rain and Groundwater – Nails used in outdoor structures, such as fences and roofs, are more susceptible to rust due to frequent rainfall.

- Use of Poor-Quality Nails – Cheap, untreated iron nails are more likely to rust quickly compared to treated or galvanized nails.

- Chemical Reactions with Cement and Other Building Materials – Some nails react with alkaline substances in cement, leading to corrosion.

- Storage in Damp Conditions – Leaving nails in open, humid environments before use can cause them to rust even before installation.

Understanding these causes is the first step toward effective rust prevention.

Choosing the Right Type of Nails

One of the best ways to prevent rust is by selecting the right type of nails for construction. The choice of nails depends on their material, coating, and intended use.

Types of Rust-Resistant Nails

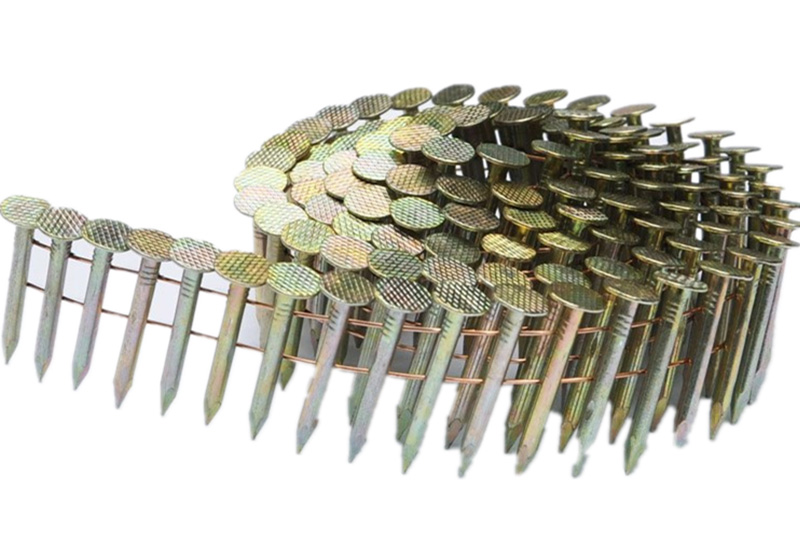

- Galvanized Nails – These nails are coated with zinc, which acts as a protective barrier against rust. They are ideal for both indoor and outdoor use in Nigerian houses.

- Stainless Steel Nails – Made from an alloy containing chromium, stainless steel nails are highly resistant to rust and corrosion. They are recommended for humid and coastal regions.

- Copper or Aluminum Nails – Though more expensive, these nails do not rust and are excellent for specialized construction, such as roofing and furniture-making.

- Brass Nails – Suitable for decorative purposes and furniture, brass nails resist corrosion but are not ideal for structural applications.

Choosing high-quality nails significantly reduces the risk of rust, ensuring durability in Nigerian homes.

Read This: Why Underground Plumbing is Becoming Popular in Nigerian Estates

Protective Coatings and Treatments

For builders who need to use iron nails, applying protective coatings can help prevent rust. Here are some common treatments:

Effective Coating Methods

- Oil or Grease Coating – Before use, dipping nails in oil or grease creates a protective layer that repels moisture.

- Paint or Varnish – Applying a coat of paint or varnish over nails can help shield them from air and water exposure.

- Anti-Rust Sprays – Available in hardware stores, anti-rust sprays provide a chemical barrier that prevents oxidation.

- Bluing Treatment – A process where nails are heated and then treated with an oil solution, forming a thin protective layer.

- Galvanization – As mentioned earlier, nails can be hot-dip galvanized, where they are coated with molten zinc for long-lasting protection.

Applying these treatments ensures that nails remain rust-free for an extended period.

Proper Storage and Handling

Even before nails are used in construction, improper storage can lead to premature rusting. To maintain their quality, nails must be stored in optimal conditions.

Best Practices for Nail Storage

- Keep Nails in a Dry, Well-Ventilated Area – Avoid storing nails in humid or damp places, such as basements or outdoor sheds.

- Use Airtight Containers – Storing nails in sealed plastic or metal containers helps prevent exposure to moisture.

- Include Moisture Absorbers – Placing silica gel packets or uncooked rice in the storage container can absorb excess humidity.

- Avoid Mixing Rusty Nails with New Ones – If some nails have already rusted, separate them to prevent the spread of corrosion.

- Store Nails Off the Ground – Keeping nails elevated on shelves reduces exposure to ground moisture.

By following these storage practices, nails will remain in good condition until they are needed for construction.

Best Construction Practices to Prevent Rust

During construction, certain techniques can minimize the risk of rust on nails used in Nigerian houses.

Rust Prevention in Construction

- Use Cement with Rust Inhibitors – Some cement products contain additives that reduce the likelihood of nail corrosion.

- Ensure Proper Drainage – Avoid water accumulation around wooden structures by installing proper drainage systems.

- Use Pressure-Treated Wood – This type of wood has been chemically treated to resist moisture and fungal growth, which can accelerate rusting.

- Seal Joints and Nail Heads – Applying sealant or caulk over nail heads prevents water from seeping into nail holes.

- Perform Regular Maintenance – Inspect nails in critical areas, such as roofs and outdoor structures, and replace any rusty ones promptly.

Incorporating these best practices helps maintain structural integrity and prolongs the life of buildings.

Alternative Fastening Solutions

In some cases, using alternatives to traditional iron nails can eliminate the problem of rust entirely.

Alternatives to Rust-Prone Nails

- Screws with Rust-Proof Coatings – Stainless steel or galvanized screws offer better grip and rust resistance compared to ordinary nails.

- Plastic or Nylon Fasteners – For lightweight applications, plastic fasteners provide a corrosion-free solution.

- Adhesive Bonding – Some modern construction methods use strong adhesives instead of nails, especially for interior woodwork.

- Copper or Brass Screws – These metals do not rust and are excellent for decorative and non-structural applications.

Exploring these alternatives can provide better longevity, especially in humid or coastal environments.

Read This: Why Many Building Projects in Nigeria fail (and how to avoid it)

Conclusion

Preventing rust on nails used in Nigerian houses requires a combination of choosing the right nails, applying protective coatings, storing them properly, and following best construction practices. Investing in rust-resistant materials not only enhances the durability of homes but also reduces long-term maintenance costs.

Homeowners, builders, and construction professionals should prioritize high-quality galvanized or stainless steel nails and implement rust-prevention strategies to ensure long-lasting structures.

Do you have any other rust-prevention tips or experiences? Share them in the comments below!